Fali De® Automatic On-site Foaming Equipment Wins High-Quality Certificate

2025/8/11 15:29:34

Fali De® automatic bag-making on-site foaming equipment has been awarded the "High-Tech Product Certification Certificate". This honor stems from our strict control over every link of product design, our high-quality R&D team, and our close cooperative relations with South China University of Technology, East China University of Science and Technology, national key laboratories and authoritative experts. Continuous R&D investment has established Hanyin Technology's leading position in the market. The equipment has also been widely recognized by customers in industries such as auto parts and electromechanics.

Fali De® automatic on-site foaming equipment can generate foaming bags automatically with a simple press of a button. Meanwhile, the equipment can produce up to 20 foaming packaging bags per minute, meeting the requirements of high efficiency and speed for mass production. In addition to having the functions of handheld on-site foaming equipment, customers can easily set the size and filling amount of packaging bags through the human-machine interface, and can set to produce a single bag or multiple consecutive bags with set time intervals and quantities; in addition, continuous tubular foam can also be set, and the size and arrangement form of the tube can be adjusted.

Steps for generating and forming a single foaming bag for packaging:

1. The operator selects the size of the foaming bag and the filling amount of raw materials, presses the set parameter group, and the foaming bag will be generated automatically.

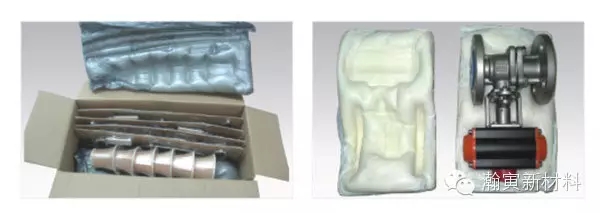

2. Put the foaming bag into the packaging box and place the product on the expanding foaming bag.

3. Make another packaging bag, place it on top of the product, and then close the packaging box.

4. Wait for the foaming to complete, and your product will be completely surrounded and protected by the two foaming bags above and below.

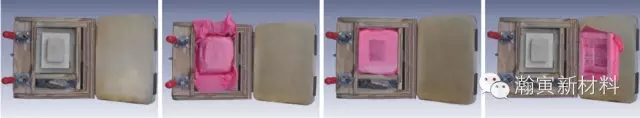

Pre-forming:

1. Prepare the pre-forming mold.

2. The air suction device sucks the foaming bag into the mold, and the foaming bag reacts and expands to form.

3. After the reaction is completed, the air blowing device in the mold cavity helps demold, and the formed packaging bag is taken out.

4. Custom-made to provide economical, efficient and uniform fixed protection.

Generation and application of continuous tubular foaming bags:

1. The size and quantity of the tube can be set programmatically.

2. Used for bottom cushioning, space filling and product wrapping.

3. Can be produced centrally and distributed to various packaging lines for use.

Recommended News

-

Hanyin Technology | The Instrumentation Exhibition (Beijing) and PTC Exhibition (Shanghai) are both in full swing!

2025-08-11

-

Hanyin Technology | Meet you at the Instrumentation Exhibition (Beijing) and PTC Exhibition (Shanghai)

2025-08-11

-

Hanyin Packaging Series - Automobile Headlight Chapter: To achieve cost reduction and efficiency improvement in headlight packaging, first you need to know these...

2025-08-11

-

Hanyin Technology | Xi'an Military Expo concluded successfully!

2025-08-11

-

Good News | Hanyin Technology was awarded "Excellent Partner" of JD Logistics' "Green Stream Project"

2025-08-11

-

Good News! Hanyin(Suzhou) New Material Technology Co., Ltd. was rated as a "High-Tech Enterprise"

2025-08-11

-

Hanyin Technology | Sinopack Guangzhou International Packaging Products Exhibition concluded perfectly!

2025-08-11

-

Green Warehousing, Hanyin Takes the Lead - Hanyin was awarded the "China Green Warehousing and Distribution Technology and Equipment Mark" authorization certificate

2025-08-11

-

Good News / Hanyin won the JD North China Annual Quality Supplier Award

2025-08-11

-

The disorderly expansion of the polyurethane insulation industry expects ultimate policy regulation

2025-08-11