Fastpacker Foam-in-bag Packaging System Ⅲ

Fastpacker foam-in-bag packaging system Ⅲ, occupied less than 1sqm. Fastpacker boasts unmatchable versatility and effciency, and one machine can deliver enough foam-filled bags to satisfy the packaing needs of one, or even more packging lines! An operator can quickly set bag length and foam fill amount on a digitalized panel. At the touch of a button, Fastpacker will feed preset film length, dispense pre-determined foam amount, and seal the bag automatically. It can realize continuous bag making and can produce more than 20 foam bags in one minute, which greatly meets the fast-paced packaging needs of the assembly line. And more than 260 sets of data can be stored, which greatly improves the packaging efficiency.

In addition, Fastpacker has the function of producing continuous tubular foam, which can be widely applied to various packaging needs. It can be packed immediately after pressing, which greatly improves the customer's production capacity and reduces the customer's cost!

Compliant with Safety and Environmental Requirements:

1. The equipment has CE certification.

2. The components have RoHS related test reports and identification certificates for the transportation conditions of ordinary goods by road and sea.

3. It is committed that no fluorine-containing components are used.

4. A national foam recycling network has been established: Polyurethane foam can be sent to any recycling station of Hanyin Technology across the country, and we guarantee to recycle it or send it to energy recovery devices for energy recovery.

Product Advantages

Continuous Tubular Foam Bag Generation and Application:

1. The size and quantity of the tubes can be program-set.

2. Used for bottom cushioning, space filling, and product wrapping.

3. Can be produced centrally and distributed to various packaging lines for use.

Equipment Supporting Consumables

1. Foaming Components

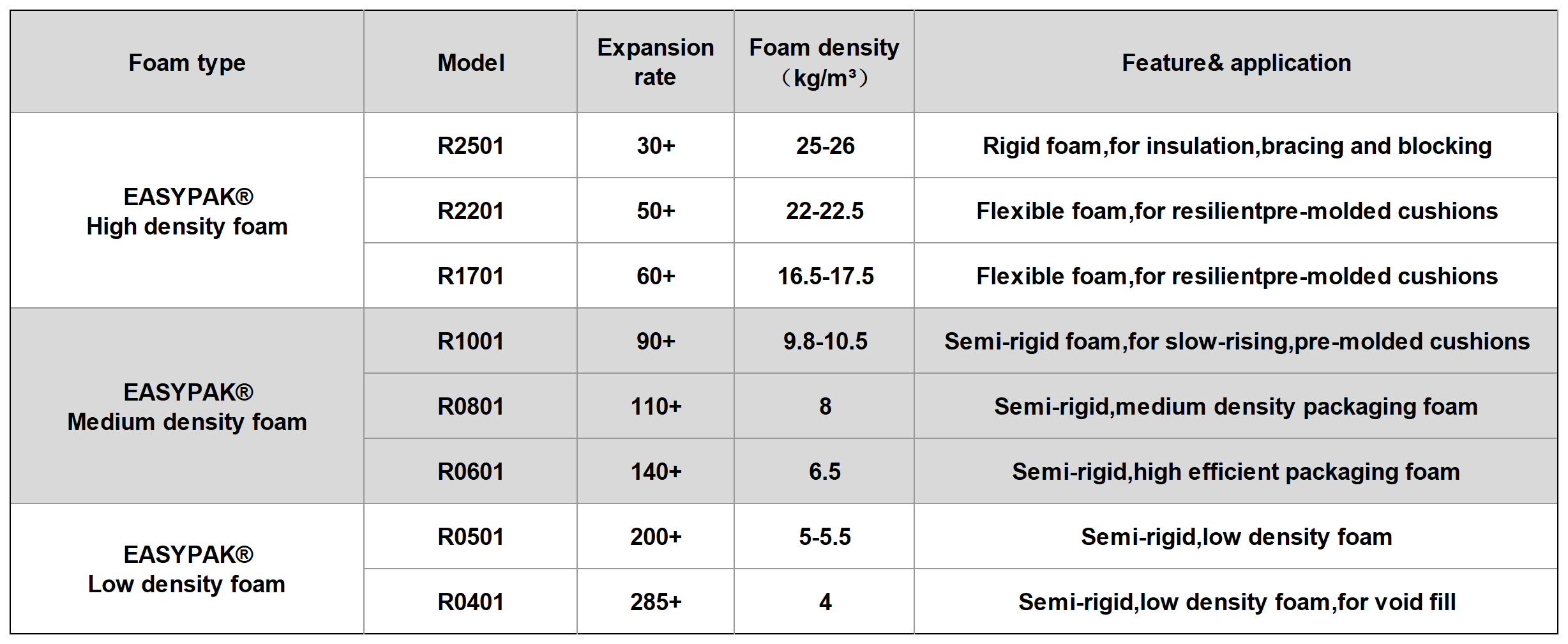

Polyurethane foaming uses A/B two types of components for mixing reaction. To meet the required foam strength and characteristics for different packaging needs, Hanyin Company provides the following formula models:

2. Foaming Film

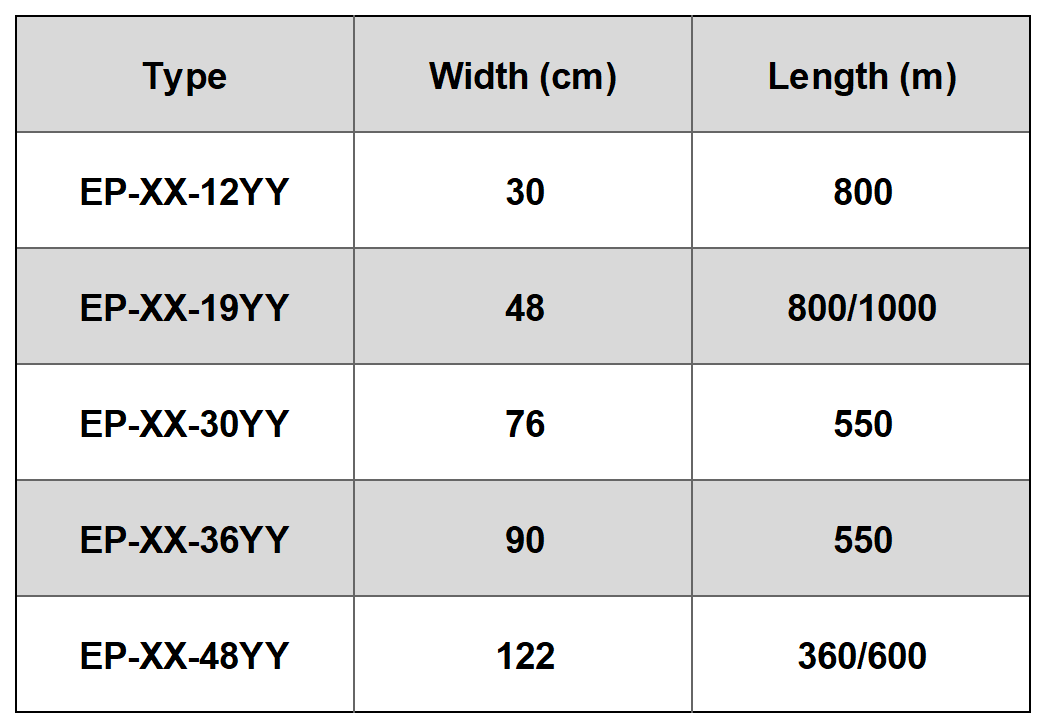

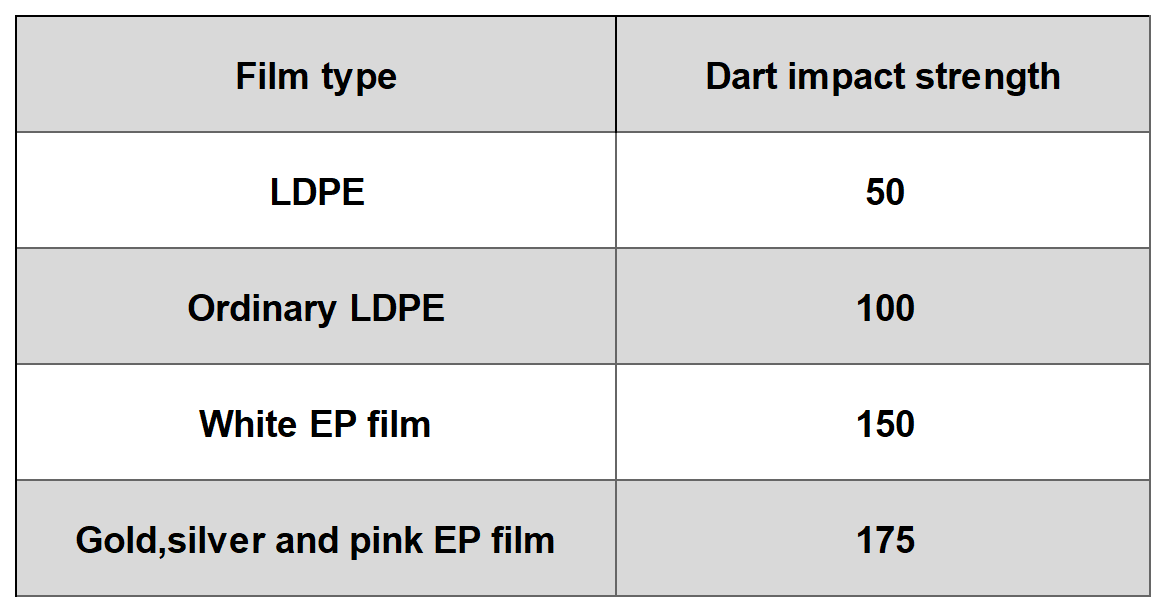

The packaging film bags, whether in terms of formula or extrusion process conditions, are specially developed. Their strength is far superior to ordinary polyethylene films, ensuring toughness and durability during the foaming reaction and subsequent use, and being less likely to break. We provide foaming films of different sizes as follows, which can correspond to different sizes of foam packaging and equipment use.

Product Operation Guide

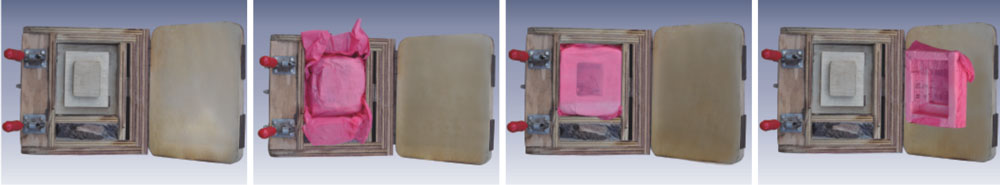

Steps for producing and packaging a single foam bag:

1. The operator selects the foam bag size and fill amount of components, then presses the set parameter group to automatically produce the foam bag.

2. Place the foam bag into the packaging box and place the product on top of the expanding foam bag.

3. Prepare another packaging bag, place it on top of the product, and close the packaging carton.

4. Wait for the foaming to complete. Your product will be completely surrounded and protected by the upper and lower foam bags.

Pre-forming:

1. Prepare the pre-forming mold.

2. The air suction device sucks the foam bag into the mold, and the foam bag reacts and expands to form.

3. After the reaction is completed, the air blowing device in the mold cavity assists in demolding, and the formed packaging bag is taken out.

4. Tailor-made to provide economical, efficient, and uniform fixed protection.

Product Operation Video