Easypacker Foam-in-place Packaging System 2002

Easypacker is a handheld on-site foaming device. The system is equipped with a precise electric metering pump, an accurate temperature monitoring system, and an excellent self-detection and diagnosis system to ensure the production of high-quality polyurethane foam.

Compliant with Safety and Environmental Requirements:

1. The equipment has CE certification.

2. The components have RoHS related test reports and identification certificates for the transportation conditions of ordinary goods by road and sea.

3. It is committed that no fluorine-containing components are used.

4. A national foam recycling network has been established: Polyurethane foam can be sent to any recycling station of Hanyin Technology across the country, and we guarantee to recycle it or send it to energy recovery devices for energy recovery.

Product Advantages

1. The electric metering pump can ensure continuous and stable chemical metering and accurate chemical mixing ratio.

2. Each electric dispenser features a patented,self-cleaning cartridge,which guarantees long service life.

3. Self-diagnostic function,intergrated with the micro-processor console,monitors operation of the system.

4. Equipped with a variety of shot modes,it can accurately control the injection volume and realize quantitative settings for multiple groups of packaging,improving packaging efficiency.

5. A thermistor is integrated in each component heater wire,which connects with the console. As a result,formula-specific,accurate temperature control in each chemical hose is realized,to ensure top foam quality.

Equipment Supporting Consumables

1. Foaming Components

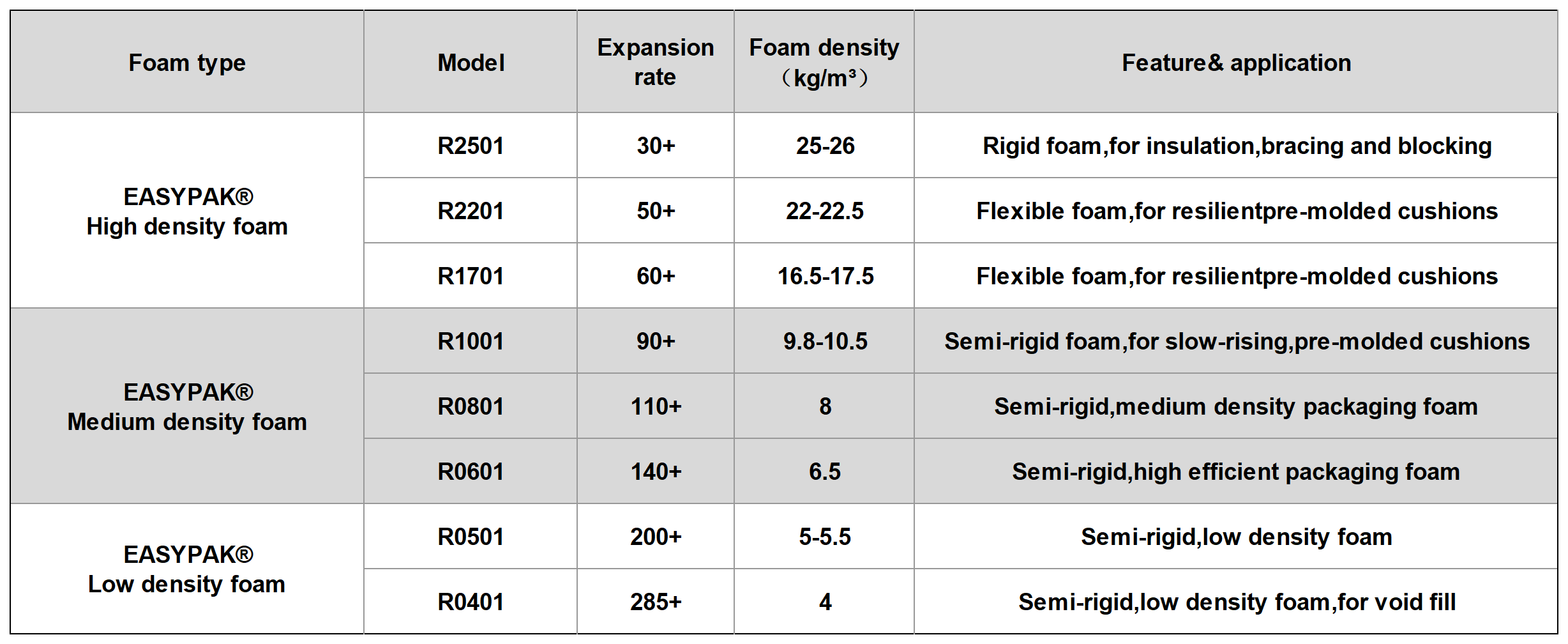

Polyurethane foaming uses A/B two types of components for mixing reaction. To meet the required foam strength and characteristics for different packaging needs, Hanyin Company provides the following formula models:

2. Foaming Film

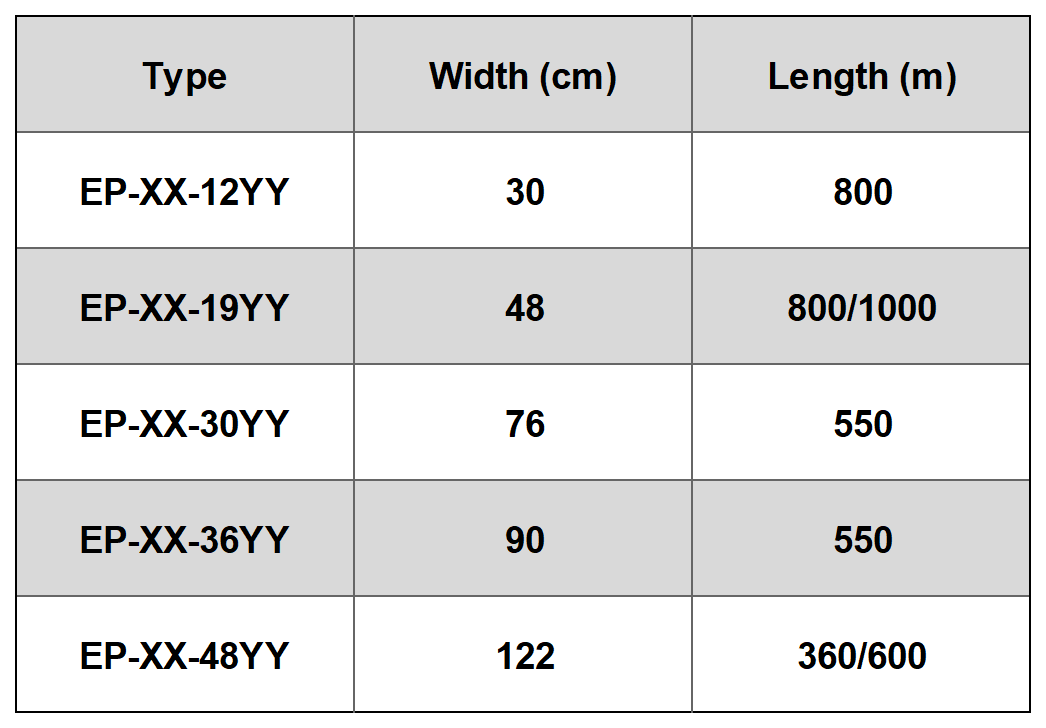

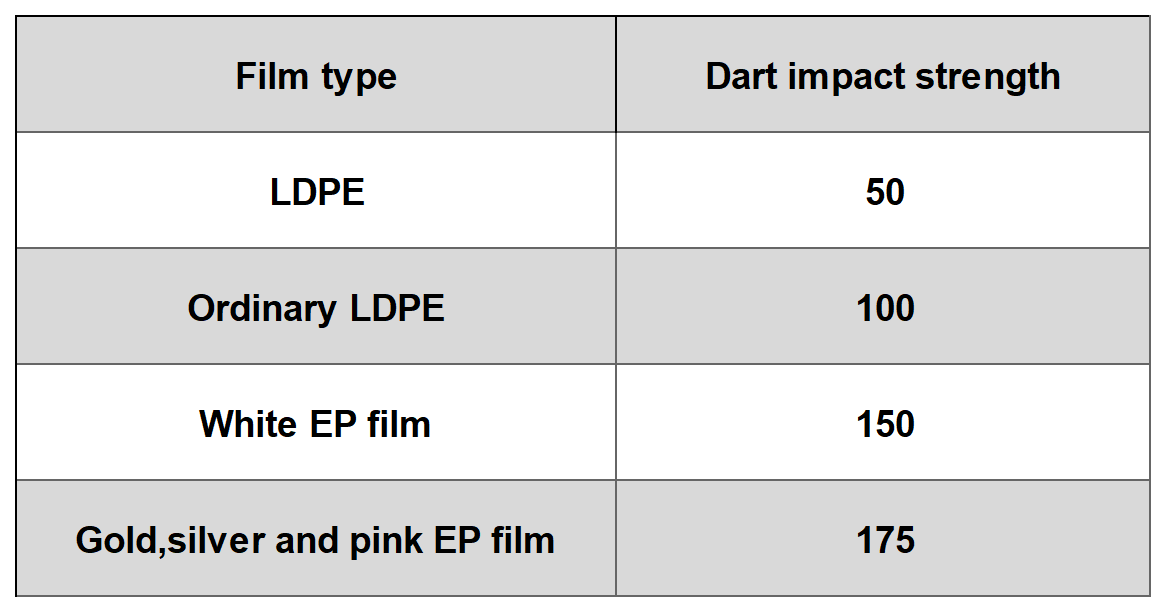

The packaging film bags, whether in terms of formula or extrusion process conditions, are specially developed. Their strength is far superior to ordinary polyethylene films, ensuring toughness and durability during the foaming reaction and subsequent use, and being less likely to break. We provide foaming films of different sizes as follows, which can correspond to different sizes of foam packaging and equipment use.

Product Operation Diagram

On-site Foaming and Forming Packaging Steps:

1. Pull the trigger on the dispenser to inject the components into the film-lined packaging box.

2. Fold the film inward and place your product on the expanding foam.

3. Place another layer of film on your product, inject the components, fold the film inward, and close the packging box.

4. Foaming is completed instantly, and your product is completely surrounded and protected by two layers of foam.

Pre-forming:

1.Prefabricate a simple wooden mold to produce foam bags of specific shapes.

2.First lay the film in the mold cavity, inject the components, fold the film inward, close the wooden mold box, and the foam bag is foamed instantly.

Product Operation Video