AirteK B Inflator CB01

|  |

The Easypak® equipment features simplicity, portability, and high efficiency. It can produce both inflatable air pillows and inflatable cushioning, making it the first choice for transportation packaging in the e-commerce and logistics industry.

Compliant with Safety and Environmental Requirements:

1. The equipment has CE certification.

2. The film has relevant harmful substance test reports from SGS.

3.The equipment is easy to operate. After placing the film on the machine, just press a button to continuously produce inflatable air pillows for use, with up to more than 160 continuous inflatable air pillows with tear lines per minute. At same time, inflatable air pillows can also be pre-produced, placed in appropriate storage boxes, and distributed to various packaging points for use.

Product Advantages

1. On-site production, manufacturing on demand, saving valuable storage space and transportation costs.

2. Air is used as the filling medium, making it an excellent environmentally friendly material. The inflated product retains air well and is reusable.

3. Lightweight, with air as the filling medium, it reduces express delivery costs.

4. A wide range of options are available, allowing for customized sizes and specifications to meet diverse packaging needs.

5.The device is compact, lightweight, fast, and easy to use. Simply press a button to produce inflatable materials in real time.

Equipment Supporting Consumables and Accessories

1. Inflatable Air Pillows (Inflatable Cushioning)

| |

The above are sample images of the products. For specific specifications, sizes and requirements, please consult our sales staff for details.

●The strength of the inflatable air pillows can reach 80kg/㎡, which can protect most items.

●Our unique film formula and process ensure excellent airtightness. Even after six months of storage, the air pillow's volume can still be maintained at least 80%.

●Upon request and with a minimum order quantity, we can print your company logo on the inflatable air pillows strap to enhance your company image.

●We have inflatable air pillows of the following sizes and thickness specifications for customers to choose from:

20cm*20cm

20cm*13cm

20cm*10cm

13um & 20um & 30um & 38um

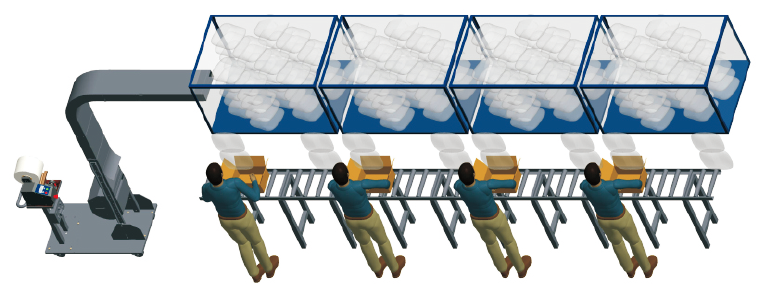

2. Conveying System (Bagcourier)

|

The conveying system is movable and can be adjusted at any time to support other work lines |

The Easypak® Airtek inflator can also be used in conjunction with the Bag Courier system to continuously produce large quantities of inflatable air pillows and distribute to multiple packaging stations. This combination of equipment efficiently produces large quantities of packaging meterial for multiple packaging stations and has been widely used in logistics packaging and distribution operations.

Our packaging technology team provides on-site assessment and planning, measurement and design, and installation and adjustment, helping customers design optimized packaging line configurations and providing a complete solution.

The Bag Courier system consists of a transport tunnel and a silo at the end of the tunnel. When connected to the Easypak® Airtek inflator, it continuously produces and delivers inflatable meterial to the silo at the end. This system offers numerous advantages, including:

1. Packaging materials are conveyed via an overhead pipe to the silo above the packaging station, saving valuable floor space eliminating clutter.

2.Using the Bag Courier system, a single air pillows packaging system can simultaneously support multiple packaging stations, effectively reducing customers' equipment investment costs.

3. The entire conveyor system is mobile, allowing for easy relocation and support of bottleneck stations.

Product Operation Video